Table of contents

- 1. Intro to Stats and Collecting Data55m

- 2. Describing Data with Tables and Graphs1h 55m

- 3. Describing Data Numerically1h 45m

- 4. Probability2h 16m

- 5. Binomial Distribution & Discrete Random Variables2h 33m

- 6. Normal Distribution and Continuous Random Variables1h 38m

- 7. Sampling Distributions & Confidence Intervals: Mean1h 3m

- 8. Sampling Distributions & Confidence Intervals: Proportion1h 12m

- 9. Hypothesis Testing for One Sample1h 1m

- 10. Hypothesis Testing for Two Samples2h 8m

- 11. Correlation48m

- 12. Regression1h 4m

- 13. Chi-Square Tests & Goodness of Fit1h 20m

- 14. ANOVA1h 0m

6. Normal Distribution and Continuous Random Variables

Standard Normal Distribution

Problem 5.2.24

Textbook Question

In Exercises 21ŌĆō24, a control chart is shown. Each chart has horizontal lines drawn at the mean mu, at mu ┬▒2sigma, and at mu┬▒3sigma. Determine whether the process shown is in control or out of control. Explain.

An engine part has been designed to have a diameter of 55 millimeters. The standard deviation of the process is 0.001 millimeter.

Verified step by step guidance

Verified step by step guidance1

Step 1: Understand the control chart. The chart shows the mean (╬╝ = 55 mm), upper control limits (╬╝ + 2Žā and ╬╝ + 3Žā), and lower control limits (╬╝ - 2Žā and ╬╝ - 3Žā). The standard deviation (Žā) is given as 0.001 mm.

Step 2: Calculate the control limits. Use the formulas for the upper and lower control limits: ╬╝ ┬▒ 2Žā and ╬╝ ┬▒ 3Žā. For example, ╬╝ + 2Žā = 55 + (2 ├Ś 0.001) = 55.002 mm, and ╬╝ - 2Žā = 55 - (2 ├Ś 0.001) = 54.998 mm. Similarly, calculate ╬╝ ┬▒ 3Žā.

Step 3: Analyze the data points on the control chart. Observe whether the data points fall within the control limits (╬╝ ┬▒ 3Žā). If all points are within these limits, the process is in control. If any point falls outside these limits, the process is out of control.

Step 4: Check for patterns or trends. Even if all points are within the control limits, look for systematic patterns (e.g., consecutive points above or below the mean) that might indicate a potential issue with the process.

Step 5: Conclude whether the process is in control or out of control. Based on the observations, determine if the process is stable and consistent or if corrective actions are needed.

Verified video answer for a similar problem:

Verified video answer for a similar problem:This video solution was recommended by our tutors as helpful for the problem above

Video duration:

3mPlay a video:

Was this helpful?

9:47m

9:47mWatch next

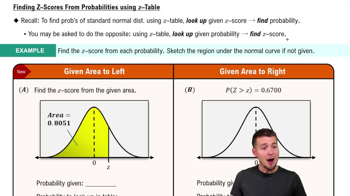

Master Finding Standard Normal Probabilities using z-Table with a bite sized video explanation from Patrick

Start learning